Trustworthy Lift Maintenance Repair: Prevent Failures and Downtime

Trustworthy Lift Maintenance Repair: Prevent Failures and Downtime

Blog Article

Unlocking the Keys to Reliable Lift Repairs: Professional Insights Exposed

In the world of lift fixing and upkeep, revealing the techniques that lead to reliable and reliable service is comparable to understanding an intricate puzzle. Expert understandings offer as the directing light through the maze of obstacles encountered by upkeep professionals in the vertical transportation sector. By delving into the midsts of positive methods, troubleshooting techniques, and the constant quest of skill enhancement, the path to raising maintenance requirements discloses itself. As we get started on this trip to demystify the keys behind streamlined lift fixings, a globe of opportunities arises, promising a future where downtime is reduced, safety is prioritized, and operational quality comes to be the norm.

Common Lift Fixing Obstacles

Another common difficulty in lift repair work is the lack of correct maintenance records. Without exact upkeep documents, repair work professionals may have a hard time to detect concerns effectively or prepare for potential troubles. This can result in longer repair service times and increased costs as professionals function to repair problems without historical information to assist them.

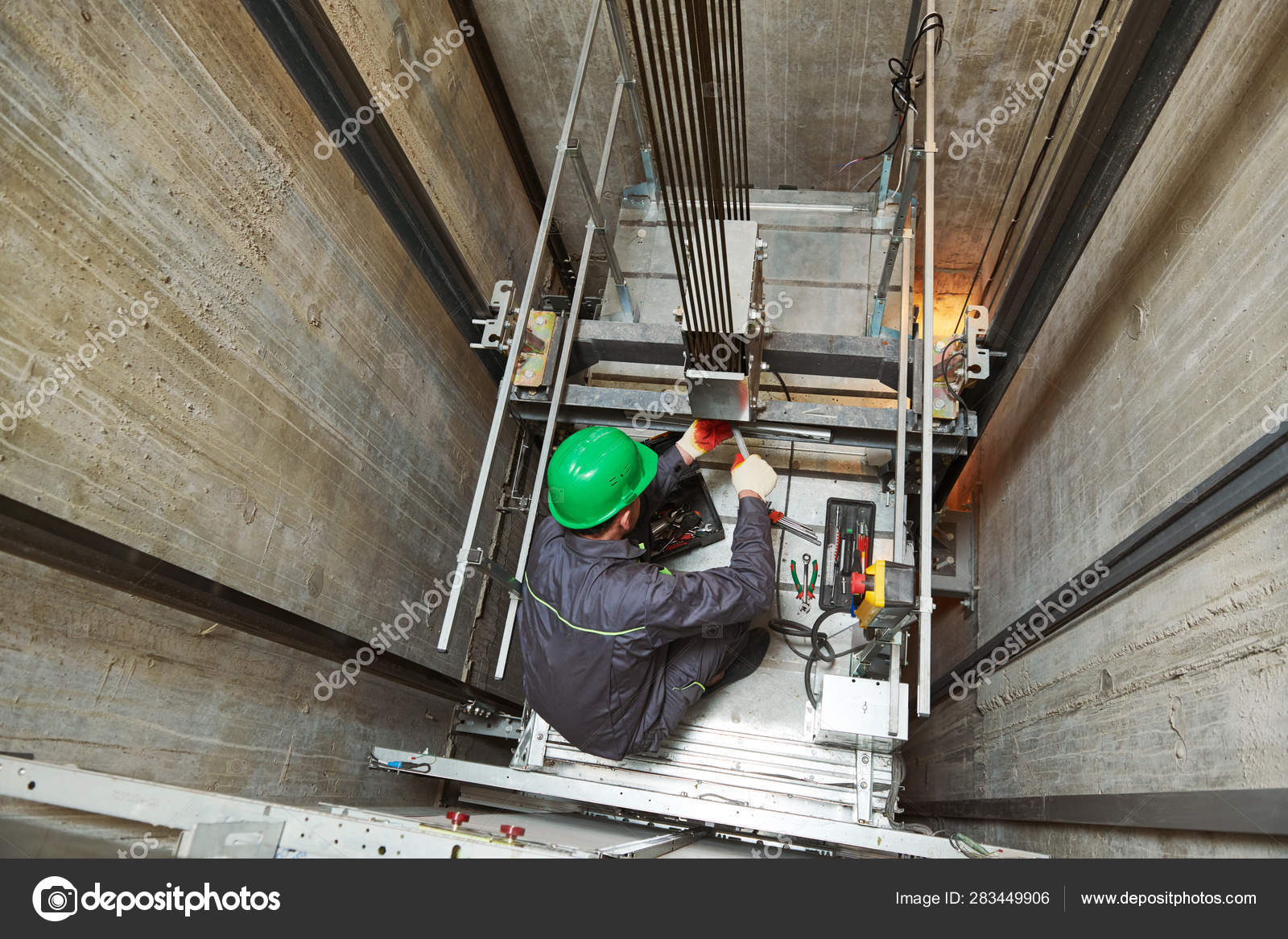

In addition, access concerns within lift shafts can position significant difficulties during repairs. Limited space, uncomfortable angles, and intricate equipment can make it hard for technicians to reach the necessary components for repair, lengthening the total repair service process - Lift Maintenance Repair. By dealing with these usual challenges proactively, lift repair service professionals can boost functional effectiveness and make sure the smooth functioning of vertical transportation systems

Proactive Maintenance Strategies

Carrying out positive maintenance strategies is critical for guaranteeing the longevity and optimum performance of lift systems. By embracing a positive method to maintenance, structure supervisors and lift upkeep teams can attend to potential concerns prior to they intensify right into pricey repair services or downtime. One effective strategy is to establish a regular upkeep routine that consists of extensive inspections, lubrication of moving parts, and testing of safety and security features.

In addition, investing in training programs for maintenance personnel can enhance their skills in determining possible concerns and executing precautionary maintenance tasks effectively - Lift Maintenance Repair. By encouraging upkeep teams with the knowledge and tools needed to proactively keep lift systems, building proprietors can reduce disruptions, expand the life-span of their lifts, and make sure a dependable and safe vertical transport experience for owners

Repairing Methods

Effective fixing strategies are essential for promptly determining and fixing problems with lift systems to minimize downtime and ensure optimal performance. One effective method is to begin with a thorough visual assessment of the lift parts, inspecting for any type of noticeable indicators of wear, misalignment, or damage.

Enhancing Repair Skills

Enhancing proficiency in lift system repair work is a basic element of guaranteeing ideal functionality and lessening operational interruptions. Lift service technicians must continuously function on honing their fixing skills to fulfill the needs of contemporary lift systems.

Additionally, staying updated with the most current developments in lift technology is important for technicians looking to boost their fixing skills. This includes proactively seeking information regarding new elements, software updates, and upkeep methods to effectively identify and remedy problems. By investing effort and time right into continuous knowing and sensible experience, elevator technicians can considerably increase their repair competencies and add to the effective functioning of lift systems.

Raising Upkeep Standards

Raising upkeep standards in lift systems is vital for making sure extended operational performance and security. Routine maintenance not just enhances the efficiency of lift systems yet also decreases the danger of unexpected malfunctions and makes sure the safety of customers. By adhering to strict upkeep procedures, lift owners and operators can substantially lower the likelihood of pricey repair work and downtime.

Implementing a thorough upkeep routine that consists of routine examinations, lubrication of moving parts, and aggressive replacement of worn components is crucial. Using advanced innovations like IoT sensors and predictive maintenance software can help in checking the lift's condition in real-time, allowing prompt interventions prior to issues intensify. Furthermore, giving continual training for upkeep personnel on the most up to date industry standards and ideal practices is crucial for promoting see this site upkeep excellence.

Additionally, promoting a culture of liability and interest to detail among maintenance groups can better elevate maintenance requirements. Encouraging open interaction channels for reporting and addressing maintenance concerns quickly can help in keeping a high degree of lift system reliability. Eventually, by prioritizing and elevating maintenance requirements, lift systems can run successfully and securely for an extended duration.

Conclusion

In verdict, reliable lift repair services require aggressive upkeep approaches, repairing strategies, and enhanced repair work skills. By resolving usual difficulties and raising maintenance requirements, upkeep professionals can effectively guarantee the smooth operation of lifts - Lift Maintenance Repair. Carrying out these expert insights can cause boosted efficiency, lowered downtime, and raised security for both guests and devices

In the world of lift find here repair service and maintenance, discovering the methodologies that lead to reliable and efficient service is similar to decoding an intricate puzzle.Another widespread difficulty in lift repair work is the absence of correct upkeep records. By taking on a proactive strategy to maintenance, structure managers and lift maintenance teams can attend to prospective issues before they rise into expensive fixings or downtime.In final thought, reliable lift repair work require positive upkeep techniques, troubleshooting methods, and improved repair skills. By attending to typical challenges and elevating upkeep criteria, maintenance professionals can efficiently make sure the smooth operation of lifts.

Report this page